About Us

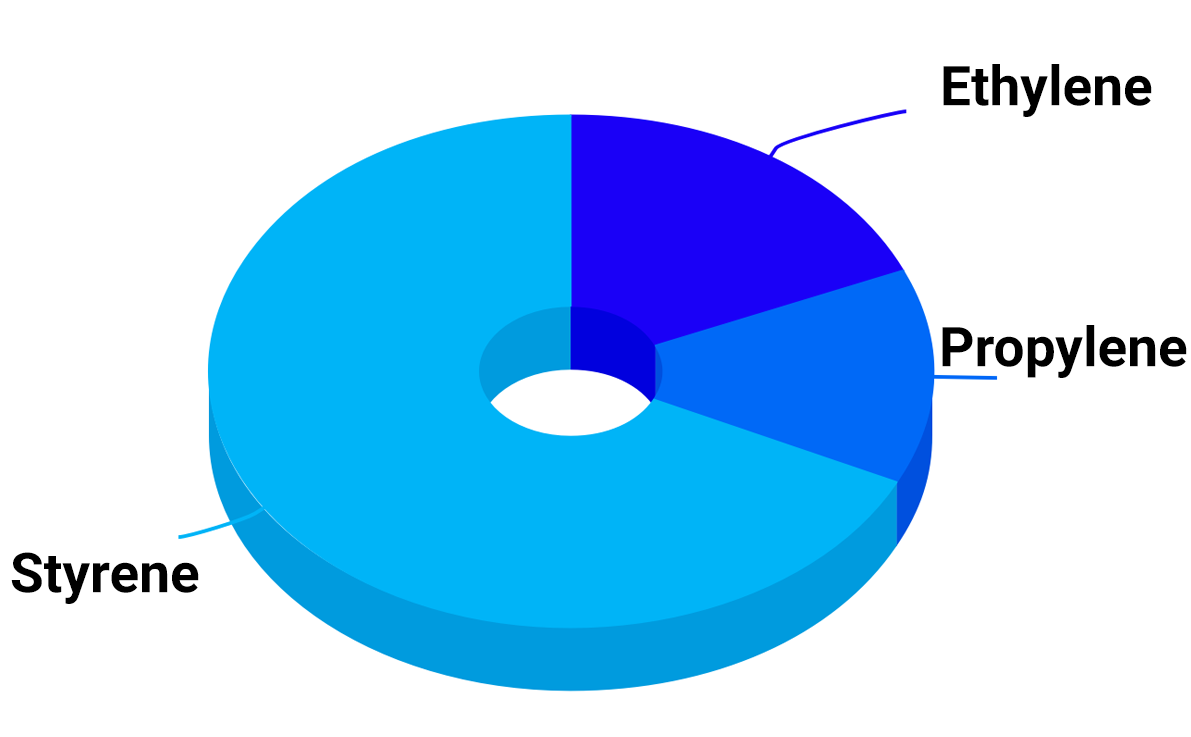

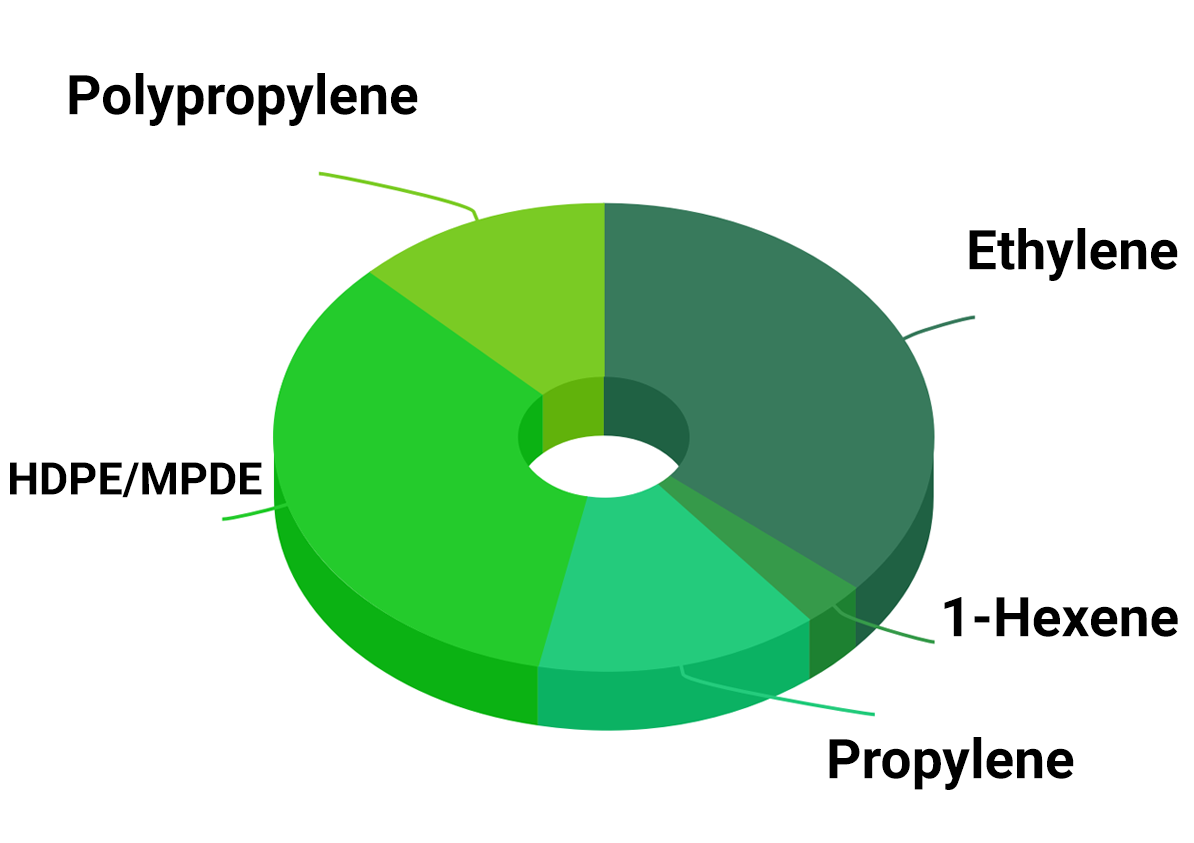

Saudi Industrial Investment Group (SIIG) with Chevron Phillips Chemical Company LLC, through a wholly owned affiliate Arabian Chevron Phillips Petrochemical Company (ACP), has two 50/50 joint venture projects in the Eastern Province Industrial City of Al-Jubail: Saudi Chevron Phillips Company (SCP) and Jubail Chevron Phillips Company (JCP).